Balancing Amino Acids in Dairy Cow rations with KESSENT™ M, the most efficient source of rumen-protected methionine for ruminants

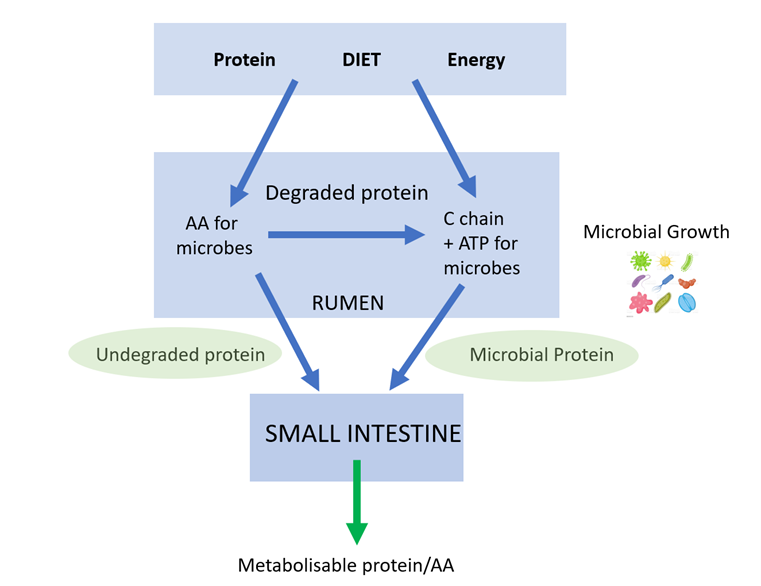

Ruminant protein nutrition has evolved over the past decades, starting from determining crude protein (CP) requirements in the late 1960s, where research was focused on how much protein was needed for the rumen and how much was needed for the cow's general maintenance and milk production. Over time with scientific advancements in the fields of chemistry, biochemistry and physics, a better understanding of protein metabolism allowed us to calculate the specific requirements of dietary protein (N), which can be classified into two broad categories: Rumen degradable protein (RDP) and rumen undegradable protein (RUP).

Rumen degradable protein is the dietary protein degraded by rumen microorganisms in the presence of a suitable energy supply and provides most of the Nitrogen (N) that is required for microbial crude protein (MCP) synthesis.

Rumen undegradable protein is the dietary protein that escapes degradation in the rumen and is digested by the host animal's enzymes in the small intestine. In addition to true protein, RDP also includes non-protein nitrogen (NPN).

Ruminal microflora continually passes out of the rumen to the abomasum and small intestine, where they die and are then digested by enzymes in the small intestine to provide individual amino acids (AA). Amino acids are also derived from the digestion of RUP. Ruminants absorb individual AA, and the profile and concentration of AA absorbed will dictate the levels of production that the cows will achieve. In other words, once there is one or more AA in short supply at the small intestine, the cows would not be able to fully express their genetic potential, and therefore milk production will be compromised.

When these two sources of AA are digested and absorbed in the small intestine they are collectively referred to as metabolizable protein (MP). Therefore, ruminants utilize dietary crude protein as a source of individual AA as we have illustrated:

C: carbon

AA: amino acids

Figure 1. Metabolisable protein/ AA concept description. Author design

The 20 primary AA in animal nutrition can be divided into two groups: Essential amino acids (EAA) and non-essential amino acids (NEAA) (Table 1). The EAA cannot be synthesized by the animal in sufficient amounts or not fast enough to fulfil the requirements for protein synthesis. On the other hand, NEAA can be synthesized by the animal in sufficient amounts.

Table 1. Essential and non-essential amino acids in alphabetical order

|

Essential amino acids |

Non-essential amino acids |

|

Arginine |

Alanine |

|

Histidine |

Asparagine |

|

Isoleucine |

Aspartic Acid |

|

Leucine |

Cysteine |

|

Lysine |

Glutamine |

|

Methionine |

Glycine |

|

Phenylalanine |

Glutamic Acid |

|

Threonine |

Serine |

|

Tryptophan |

Proline |

|

Valine |

Tyrosine |

It has long been known that cows require AA for the synthesis of body tissue and for regulatory, protective, and secretory proteins. Thousands of different proteins must be synthesized every day. It is also well documented that the AA composition of each protein is different, but the AA composition of a protein is the same every time it is synthesized because protein synthesis is a genetically determined event. Therefore, the AA composition of synthesized proteins is not affected by the amount or AA profile of absorbed AA.

Amino acids and not protein per se are the required nutrients for ruminants. Absorbed AA, used mainly as building blocks for the synthesis of proteins, are vital to the maintenance, growth, reproduction, and lactation of dairy cattle (NRC, 2001). Amino acids are essential as the building blocks for the synthesis of tissue and milk proteins. Although to a lesser extent, absorbed AA are also required as precursors for the synthesis of other body metabolites. Amino acids also serve as precursors for gluconeogenesis, and all can be converted into fatty acids or serve as immediate sources of metabolic energy when oxidized to CO2.

While the profile of absorbed AA does not affect the AA used in metabolism and production, the profile of absorbed EAA does affect the amount of protein that can be synthesized. This is widely documented in swine (NRC, 1998) and poultry (NRC, 1994). It is well documented that when EAA are absorbed in the profile as required by the animal, their efficiency of use for protein synthesis is maximized, and the requirement for total absorbed AA is reduced to a minimum. Therefore, catabolism of "left-over" AA is minimal, and urinary N excretion is reduced. In contrast, the efficiency of the use of AA for protein metabolism and production is less efficient when the profile of absorbed EAA is less than ideal. In this case, it is the supply of the first limiting EAA that determines the extent of protein synthesis, not the total AA supply.

Maintaining or increasing high production levels is a challenge for nutritionists, who need to find ways to provide correct levels of nutrients needed for production and health without causing environmental concerns. Feed formulation of dairy cows is the factor with the greatest impact on the cost of milk production. Another important factor to be considered in the definition of the nutritional strategy of dairy cows is the fluctuation in milk price. Thus, the use of feed programs that address the economic sustainability of production associated with lower costs is desirable.

One option to ensure or optimize sustainable production is the balancing of amino acids in dairy cow rations, which has the potential to:

- • Reduce the cost of diets;

- • Improve the efficiency of protein use;

- • Increase production of milk solids;

- • Provide more energy and improve nutritional balance;

- • Reduce environmental pollution.

Milk protein is produced from the amino acids of the diet or the ruminal microflora, as previously discussed. Amino acids are the building blocks of essential proteins and nutrients and are therefore critical for milk production. Rumen microorganisms can synthesize amino acids, but there is a big difference between methionine concentration in milk protein and the contribution of methionine to microbial protein, which will be normally insufficient. It is known that the deficiency of a single essential amino acid can restrict milk protein production to the level sustained by the most limiting amino acid.

Why do dairy cows need methionine?

In high-production cow rations, methionine is the first limiting amino acid for milk production, which means that it determines the productive performance of dairy cattle (Schwab, 2012). In addition, methionine is a functional amino acid that plays an important role in general metabolism and is responsible for maintaining various immune functions (Schwab, 2017).

KESSENT™ M, a rumen-protected methionine produced by Kemin, provides the essential amino acid methionine in a highly concentrated form to balance dairy cow feed, becoming an essential tool for optimizing profitability in milk production.

Kemin is one of the world's leading companies in Animal Nutrition that supply over 500 speciality ingredients and offer product solutions to customers in more than 120 countries. Our line of business, Animal Nutrition, provides innovative, cost-effective and sustainable solutions for the feed industry. An excellent example of our commitment to innovation is the investment in Research and Development. We have more than 300 patents in our portfolio, which exemplifies that latter statement: scientific innovation is key for Kemin.

KESSENT™ M, one of our main products for ruminants, is the most efficient source of protected methionine in the market. Its particle size allows rapid rumen escape with minimum methionine loss. It contains 74% DL-methionine with 80% bioavailability. Its ruminal protection rate of 90% and digestibility of at least 90% guarantee KESSENT™ M to provide 60% metabolizable methionine according to a robust study conducted by Dr Calsamiglia’s group (Kihal et al, 2021) and replicated by from a second trial from Flanders Research Institute for Agriculture, Fisheries and Food. Utilizing a unique coating technology, the product is stable in all mixing and transport procedures in a feed factory and in a total blend.

How does KESSENT™ M compare to competitors in terms of bioavailability?

In 2020, Dr Gressley and her team published a study entitled "Evaluating plasma methionine in response to feeding three rumen-protected methionine products", where the main objective was to provide a comparison between products in the market with regards to their capabilities to increase methionine plasma levels in dairy cows. To contextualize the study, it is widely accepted that plasma methionine (Met) is a strong indicator of the bioavailability of rumen-protected Met products and is directly influenced by the intestinal absorption of Met. The study examined the comparability of a new rumen-protected Met product, KESSENT™ M, to 2 currently marketed products. Ten multiparous Holstein cows, 280 ± 73 DIM, were used in a replicated 3x3 Latin square design, with 7 d experimental periods. Treatments consisted of a control diet plus 12 g/d of either KESSENT™ M (Kemin Animal Nutrition and Health, Herentals, Belgium), Product S or Product M. Cows were fed ad libitum with 33% of their daily feed allotment provided every 8 h. Milking occurred at 4:30 a.m. and 3:30 p.m. daily with milk samples collected on d 5—7 of each period. During d 5—7 of each experimental period, blood samples were collected from jugular catheters at 2, 4, 6, and 8 h after the morning feeding. The authors found that plasma Met as a % of total amino acids minus Met was 1.5085, 1.5267, and 1.3622% for KESSENT™ M, Product S, and Product M, respectively. KESSENT™ M and Product S were not found to be significantly different (P = 0.3420), however KESSENT™ M and Product M were significantly different (P < 0.0001), with KESSENT™ M yielding greater plasma Met Levels. There was a significant effect of time of sampling on plasma Met as a percentage of amino acids minus Met (P = 0.002), due to higher Met at 2 h (1.508%) than 4, 6, and 8 h (1.439, 1.447, and 1.469% respectively). Similarities in plasma Met levels between KESSENT™ M and Product S treatments would suggest comparative bioavailabilities and bioavailability greater than that of Product M.

To obtain maximum benefit with protected methionine supplementation, it is recommended to start feeding the animals with KESSENT™ M during the transition phase because it is the most critical period in the dairy production cycle and is characterized by a compromised immune system.

KESSENT™ M supplementation during the prepartum period (3 weeks before parturition) and up to 60 days of milk production show significant higher dry matter (DM) intake and energy-corrected milk production in several farm trials. In addition, liver function tends to improve with less oxidative stress and inflammation. Overall, a positive impact on herd health and higher profitability has been observed when customers utilize KESSENT™ M in their rations.

Cows have no demand for crude protein. They do, however, have a biological need for AAs. KESSENT™ M can be used to balance diets to meet AA requirements during lactation and other periods of productive life.

Without supplementation with a protected source of methionine, the methionine supplied should come from the main raw materials (soybean meal, corn...), which would normally result in a surplus of all other AA of which methionine is the first limiting. This excess leads to a nutritional imbalance, inefficient use of protein and increased nitrogen excretion.

When rations are balanced for AA, raw materials with high CP content, such as soybean meal, are completely or partially replaced by other components, such as forages or grains, always ensuring adequate amounts of energy and degradable protein in the rumen to maximize microbial protein production.

To fill the gap resulting from methionine, KESSENT™ M provides a solution to make dairy feed more sustainable and economical at the same time while maintaining performance and improving milk quality.

Overall, supplementation with KESSENT™ M will help increase the profitability of dairy farms.

References:

- Kihal, A., Rodriguez-Prado, M., Calsamilgia, S. 2021. Relative bioavailability of 3 rumen-undegradable methionine sources in dairy cows using the area under the curve technique. Journal of Dairy Science Communications. Volume 2, Issue 4, July 2021, Pages 182-185

- National Research Council. 1994. Nutrient requirements of Poultry. 9th rev. ed. Natl. Acad. Sci., Washington, DC.

- National Research Council. 1998. Nutrient requirements of Swine. 10th rev. ed. Natl. Acad. Sci., Washington, DC.

- National Research Council. 2001. Nutrient requirements of Dairy Cattle. 7th rev. ed. Natl. Acad. Sci., Washington, DC.

- Schwab, C. 2012. The principles of balancing diets for amino acids and their impact on N utilization efficiency. p.1-15. In: Proceedings of the 23rd Ruminant Nutrition Symposium. University of Florida, Gainsville, FL.

- Schwab, C. G. and G.A. Broderick. 2017. A 100-Year Review: Protein and amino acid nutrition in dairy cows. J. Dairy Sci. 100:10094–10112.

- Smith, M.S. et al. Evaluating plasma methionine in response to feeding three rumen-protected methionine products. 2020. American Dairy Science Association.